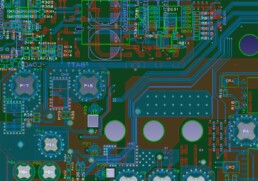

Business Case “Power”: high current cards

The requirement expressed to CAO Concept by its client, an international industrial company in the field of electrical energy supply, including wind power: to design electronic boards carrying high currents with high voltages.

In the midst of a global process regarding the ability to decarbonise energy production, particularly via renewable sources such as solar and wind, storage is an integral part of the challenges to be met. In this context, CAO Concept has worked on the design of these high current electronic boards. Its client operates on a global scale in sectors such as energy transport for large infrastructures and off-grid applications.

The main focus for CAO Concept in the design of these electronic boards was the ability to dimension the PCB tracks, taking into account the high currents carried and the thermal environment.

In concrete terms, the calculation of the track cross-section had to be optimised according to the current and the maximum temperature rise permitted, depending on the TG (glass transition temperature) of the materials used for the PCB.

Another issue in these high voltage environments is that insulation distances must comply with IPC-2221 standards. These standards provide references for determining the Minimum Conductor Spacing.

How to dimension the heat dissipation areas when designing an electronic board for high currents?

One of the problems in routing such high-current boards is the ability to optimise the components’ heat dissipation. One of the most important steps in the design process is the heat dissipation areas’ dimensioning.

Do you have a project?